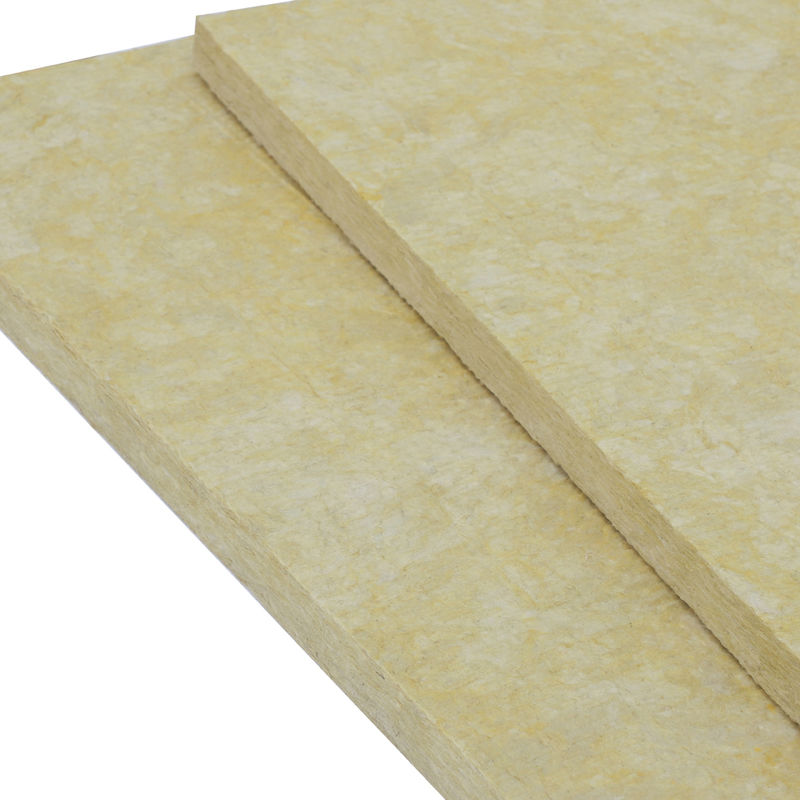

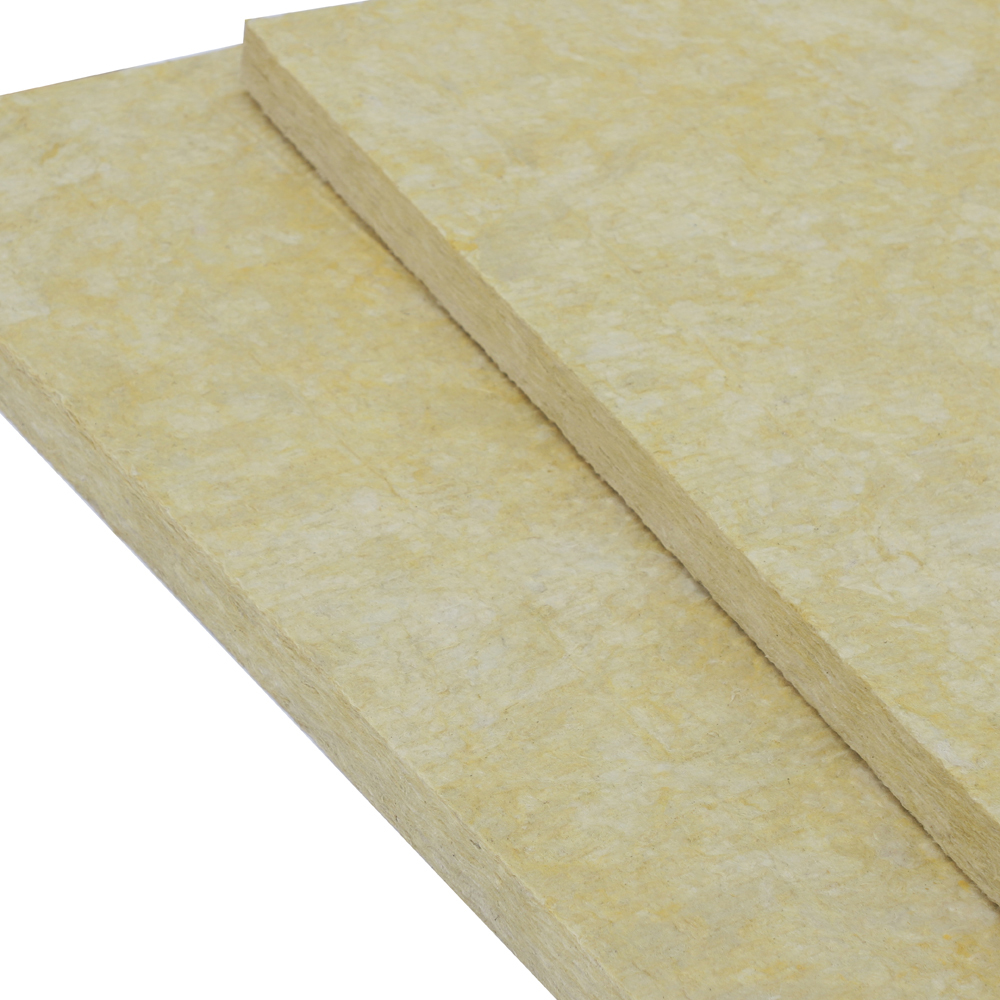

Introducción del producto de la Placa de Lana de Roca

El compromiso con la sostenibilidad se une al rendimiento en la Placa de Lana de Roca FANRYN. Fabricada con abundantes rocas naturales y producida mediante un proceso eficiente energéticamente, esta placa reduce la huella de carbono a la vez que ofrece propiedades de aislamiento excepcionales. Sus cualidades no combustibles y resistentes a la corrosión la hacen ideal para proyectos de construcción ecológica que buscan certificaciones LEED o similares.

Adecuada para muros exteriores, tejados e instalaciones industriales, apoya la conservación de energía y los objetivos de reducción de emisiones sin comprometer la seguridad ni la durabilidad.

Detalles de producción de la Placa de Lana de Roca

Parámetros del producto de la Placa de Lana de Roca

|

Propiedades

|

Placa

|

Estándares

|

|

Tolerancia de densidad

|

±10%

|

GB/T 19686-2005

|

|

Comportamiento al fuego

|

No Combustible

|

GB/T 5464-1999

|

|

|

Reacción al fuego Clase A1

|

GB/T 8624-2006

|

|

Conductividad térmica

(W/mK, a 70±5℃)

|

≤0.044

|

GB/T 10295

|

|

Diámetro de la fibra

|

7(+/-1)um

|

GB/T 5480. 4

|

|

Contenido de perdigones

(tamaño del perdigón>0.25mm)

|

≤12%

|

|

|

Contenido de humedad

|

≤0.5%

|

|

|

Contenido de materia orgánica

|

≤4%

|

|

|

Punto de fusión

|

>1000℃

|

|

Tamaño del producto de la Placa de Lana de Roca

|

Producto

|

Placa

|

|

Densidad (kg/m3)

|

40-200

|

|

Tamaño: L x A (mm)

|

600X1200

|

|

Espesor (mm)

|

30-100

|

Aplicación del producto de la Placa de Lana de Roca

Sistemas de revestimiento de muros exteriores: Previene la propagación vertical del fuego.

Conjuntos de tejados: Protege la envolvente del edificio de incendios externos.

Tabiques: Crea compartimentos resistentes al fuego para contener las llamas.

Suelos y techos flotantes: Añade una resistencia crucial al fuego a los conjuntos de suelos.

Protección estructural: Aísla la estructura de acero y protege la infraestructura crítica

Revestimiento de producción de la placa de lana de roca

Malla de alambre

Revestimiento de papel de aluminio

Tela de fibra de vidrio

Embalaje de producción de la Placa de Lana de Roca

1. bolsa de plástico

2. Bolsa retráctil de PE

Preguntas frecuentes:

P1: ¿Cómo garantizar la calidad de los productos?

A1: Nuestro experimentado equipo de control de calidad inspeccionará la calidad del producto en cada proceso

P2: ¿Cómo embalar los productos exportados?

A2: Bolsa de plástico (Embalaje estándar de exportación).

P3: ¿Cuál es su plazo de entrega para un pedido de un contenedor de 40HC?

A3: Normalmente 15-20 días laborables después de realizar el pedido

P4: ¿Cuál es su ventaja en la placa de lana de roca?

A4: Se pueden fabricar productos especiales con especificaciones especiales por encargo.

P5: Sobre el servicio postventa, ¿cómo resolver los problemas que surjan a sus clientes en el extranjero a tiempo?

A5: La garantía de nuestros productos es de un año. Si nuestros productos o embalajes presentan problemas de calidad, los reemplazaremos o compensaremos en consecuencia.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!